Al-Atheer for Industrial Solutions

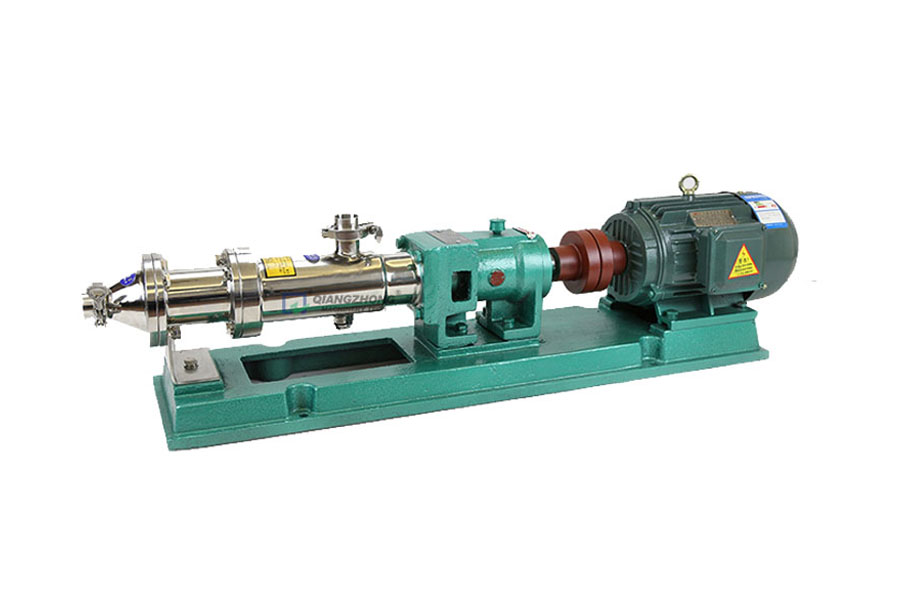

Single Screw Progressive Cavity Pump – Technical Data Sheet

Product Description

The single screw progressive cavity pump is compact, easy to maintain, and suitable for a wide range of light and heavy fluids. It delivers stable flow with minimal pressure fluctuation and strong self-priming ability.

The stator is made from food-grade elastomers (NBR, silicone, FKM), while the rotor and casing are manufactured from 304/316 stainless steel, ensuring safety in handling food, pharmaceutical, and chemical products.

The pump is ideal for transferring high-viscosity fluids and semi-solids such as tahini, hummus, honey, molasses, syrups, creams, oils, emulsions, suspensions, and more.

Working Principle

Single screw, progressive cavity pump.

Fluid advances through sealed cavities formed between the rotor and stator in a continuous spiral motion.

Flow rate is proportional to the pump’s rotational speed.

Main Features

-

Stable, non-pulsating flow.

-

Handles both low and high viscosity fluids.

-

Capable of pumping fluids containing soft solids or fibers.

-

Hygienic design with food-grade materials.

-

Easy operation, cleaning, and maintenance.

-

Long service life and wear resistance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Max. Permissible Fluid Temperature | 80°C (176°F) |

| Casing Material | Cast Iron, SS304, SS316 |

| Stator Material | NBR, Silicone, Mixed Rubber, FKM |

| Maximum Viscosity | 1×10⁶ cP |

| Maximum Drive Rating | ≤ 355 kW (475 HP) |

| Maximum Caliber | 250 mm (10 inch) |

| Maximum Discharge Side Pressure | 1.2 MPa (12 bar) |

| Flow Rate Range | 0.8 – 150 m³/h (3 – 660 US GPM) |

| Main Applications | Slurry, Foodstuff, Oil, Chemicals |

Applications

-

Oil & Water Treatment – oil-water separator, sewage treatment.

-

Shipping Industry – bilge water, scrap oil, wastewater.

-

Petroleum – crude oil, gas-water mixtures.

-

Medicine & Cosmetics – creams, emulsions, pharmaceutical liquids.

-

Food Industry – tahini, hummus, honey, syrup, cooking oil, sauces.

-

Brewing – fermentation slurry, dregs, cereal products.

-

Construction – cement mortar, lime slurry, paints.

-

Mining – ground water with solids.

-

Chemical Industry – suspensions, colloids, adhesives, oils.

-

Printing & Paper – high viscosity inks, pulp, coatings.

-

Industrial Boilers/Power Plants – coal-water slurry.

Performance Data

| Model | Capacity (m³/h) | Speed (r/min) | Pressure (MPa) | Motor Power (kW) | Head (m) | NPSHr (m) | Inlet (mm) | Outlet (mm) | Max Grain Dia. (mm) | Max Fiber Length (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| G20-1 | 0.8 | 960 | 0.6 | 0.75 kW – 6P | 60 | - | 25 | 25 | 1.5 | 25 |

| G25-1 | 2 | 960 | 0.6 | 1.1 kW – 6P | 60 | - | 32 | 25 | 1.5 | 25 |

| G30-1 | 3 | 960 | 0.6 | 1.5 kW – 6P | 60 | - | 32 | 25 | 1.5 | 25 |

| G35-1 | 5 | 960 | 0.6 | 3 kW – 6P | 60 | 4 | 50 | 32 | 3 | 45 |

| G40-1 | 8 | 960 | 0.6 | 4 kW – 6P | 60 | - | 65 | 40 | 3.8 | 45 |

| G45-1 | 12 | 960 | 0.6 | 5.5 kW – 6P | 60 | - | 80 | 50 | 5 | 50 |

| G50-1 | 20 | 960 | 0.6 | 7.5 kW – 6P | 60 | 4.5 | 100 | 80 | 5 | 50 |

| G60-2 | 30 | 960 | 0.6 | 11 kW – 8P | 120 | - | 125 | 100 | 6 | 60 |

| G70-2 | 40 | 720 | 0.6 | 15 kW – 8P | 120 | - | 150 | 125 | 8 | 70 |

| G80-2 | 65 | 720 | 0.6 | 18.5 kW – 8P | 120 | 5 | 150 | 125 | 8 | 70 |

| G85-1 | 80 | 720 | 0.6 | 22 kW – Gear Motor | 120 | - | 150 | 150 | 10 | 80 |

| G100-2 | 100 | 500 | 0.6 | 30 kW – Gear Motor | 160 | - | 200 | 200 | 15 | 110 |

| G125-2 | 150 | 400 | 0.6 | 37 kW – Gear Motor | 160 | - | 200 | 200 | 15 | 110 |

| G135-2 | 150 | 380 | 0.6 | 55 kW – Gear Motor | 160 | - | 250 | 200 | 20 | 150 |

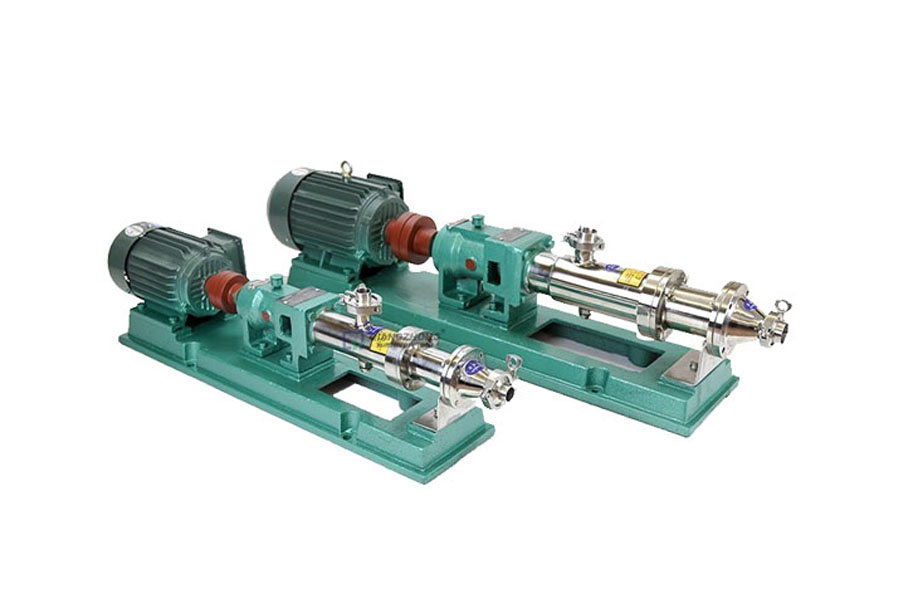

Installation & Dimensions

-

Pumps can be equipped with fixed speed motors, CVT motors, or variable frequency drives.

-

Recommended to reduce speed for high-viscosity or solid-containing fluids.

-

Installation drawings and detailed dimensions are available upon request.

📌 Prepared by:

Al-Atheer for Industrial Solutions

Industrial Pumps & Processing Equipment Division